John Deere Models: 9650, 9660, 9670, 9750, 9760, 9770, 9860, 9870, S550, S650, S660, S670, S680, S690, S760, S770, S780, S790

Case IH Models: 1680, 1688, 2188, 2377, 2388, 2577, 2588, 5088, 6088, 7088, 5130, 6130, 7130, 5140, 6140, 7140, 7010, 8010, 7120, 8120, 9120, 7230, 8230, 9230, 7240, 8240, 9240, 7250, 8250, 9250

Crops: Corn, Soybeans, Wheat, Milo, Rice, Canola, & More

Includes: 3 Threshing/Separating Concaves, and 3 Cover Plates (included)

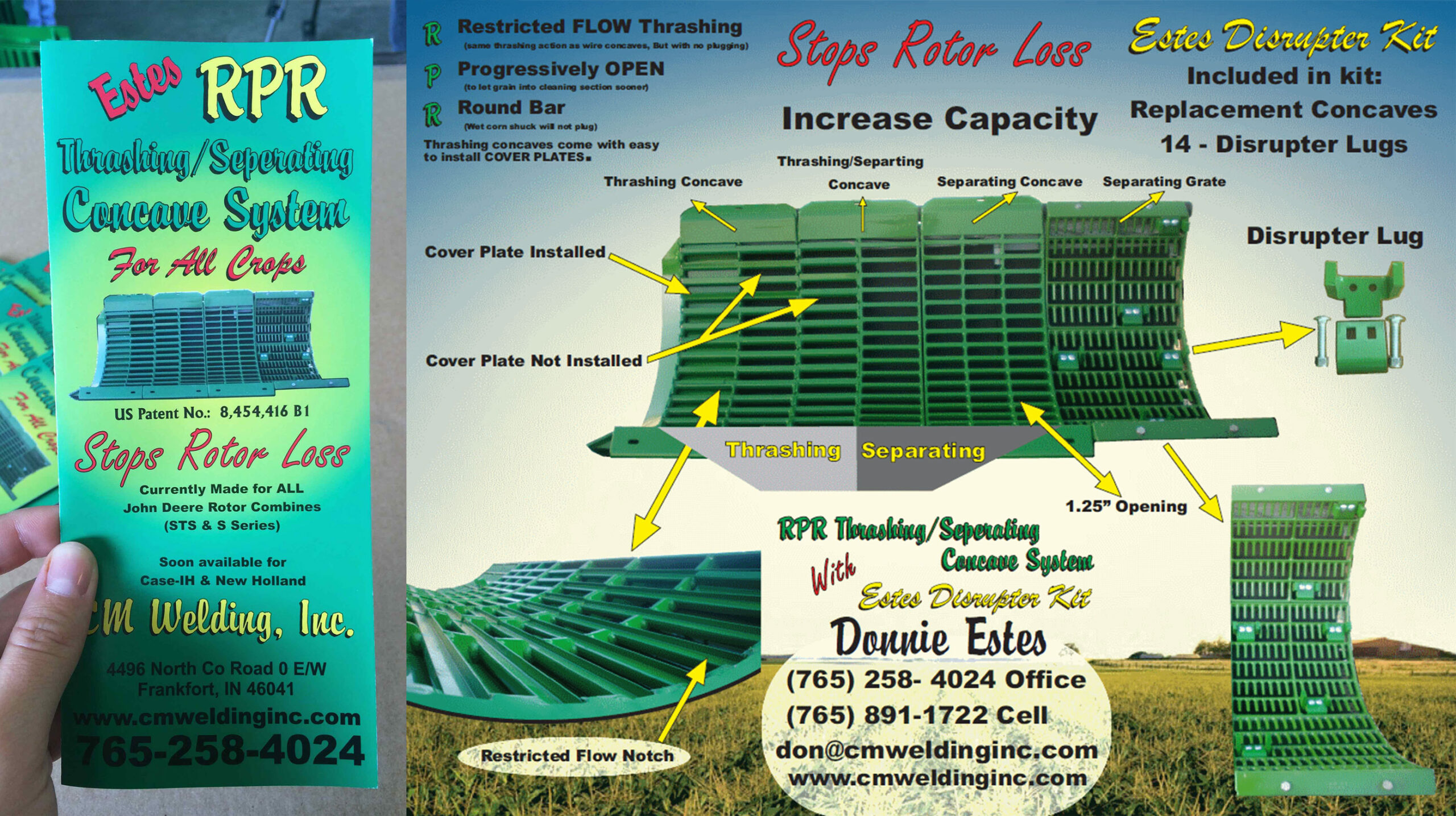

In 2012 CM Welding, Don Estes first released The RPR Concave System™ (below)

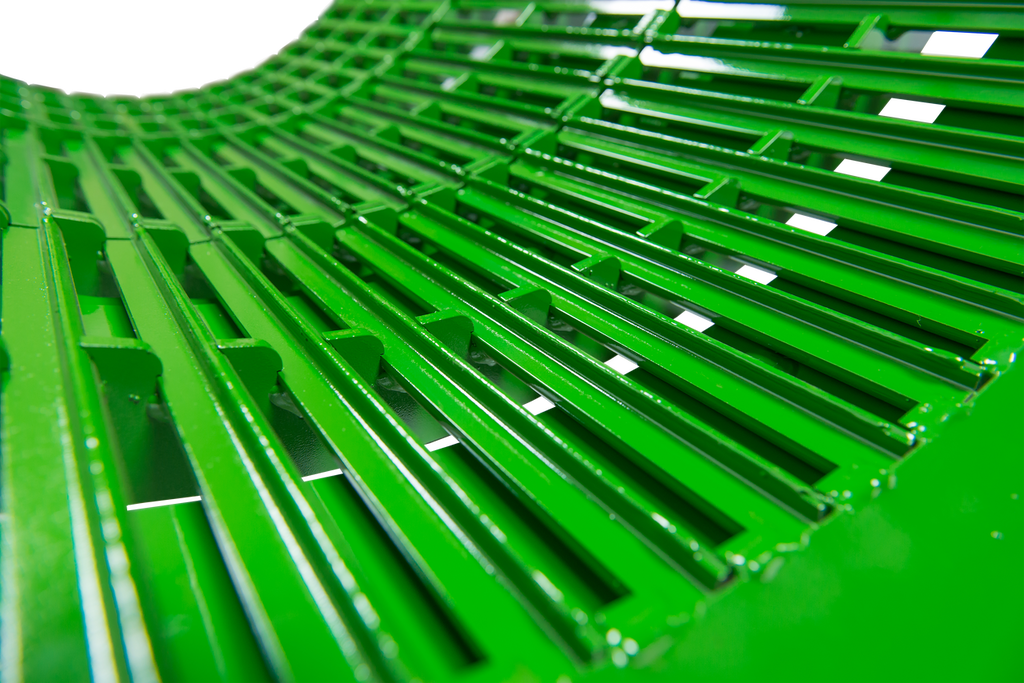

The RPR Concave System was engineered to “STOP” rotor loss, by allowing more grain to escape in the concaves preventing an overloaded separator. The “Pacman” round bar with a patented 90 degree notch in it was designed to restrict the crop flow and force material to rub on material. The concave is made with 1″ round bars with the 90 degree restricted flow notch with progressive open bar spacing. Where the crops comes in, on the right side of the combine, the spacing is 7/8″ between the bars and progresses to a 1-1/8″ opening between the bars on the left side of the combine.

This design enables the separation of crops in the threshing area, reducing the likelyhood of an overloaded separator which is the primary cause of rotor loss. The progressive bar spacing within the concave ensures that more grain is effectively unloaded as it passes through the concave system. This flow was increased by 68% over stock round bars with 5/8″ bars and 5/8″ openings. The adjustable covers are designed to hold in material to encourage more grain-on-grain threshing, they are typically used in all crops except corn. This is all followed up by the placing of the Disrupter lugs into your existing separating grates to fluff up the crop mat to finish the separation operation.

R | Restricted Flow Threshing forces more grain-on-grain threshing

P | Progressively Open to increase capacity so grain can be separate quickly

R | Round Bar with our patented notch gives a cleaner thresh yet still prevents plugging

Stock round bar concaves work reasonable well in that they don’t plug often in good conditions, and therefore can be “universally” used across crops and conditions, but the rotor loss and grain damage in corn is unacceptable. There is more mechanical damage done to grain by round bars than anything else. The 90 degree bar is more aggressive than a round bar, with the 90 degree notch creating a square edge so it threshes like a square bar, but with round bar advantages. The patented RPR Concave System reduces plugging, rotor loss, and increases ground speed. To go from corn to beans (or other harder threshing crops), all you have to do is open the machine and install the cover plates.

The Original RPR Concave System by CM Welding, Donnie Estes located in Frankfort, Indiana. Over the years thousands of farmers have purchased from CM Welding, and “come by the shop” where the RPR calls home. The RPR Concave system was designed, tested and patent of the 90 degree bar filed in 2012. Distributed by Estes Performance Concaves and dealers worldwide.

Copyright © 1995-2024 CM Welding, Inc. All Rights Reserved.

* The RPR Concave System™ was designed and patented by CM Welding, Donnie Estes, in 2012, and was first introduced to the public for sale in the same year. The Rotor Loss Kit™ and Disrupters™ by CM Welding, Donnie Estes, were released prior to the RPR Concave System. In July 2018, Copperhead Concave Systems, LLC also licensed the IP and technologies for use and sale. The RPR Concave System™, technologies and patents did not exist prior to 2012, and the RPR Concave System™ was only available for sale through CM Welding and its dealers before the patent and technologies were licensed in July 2018 by Copperhead Concave Systems, LLC. The RPR Concave System™ is still available for sale through CM Welding, Estes Performance Concaves, and other select dealers.

Reviews

There are no reviews yet!