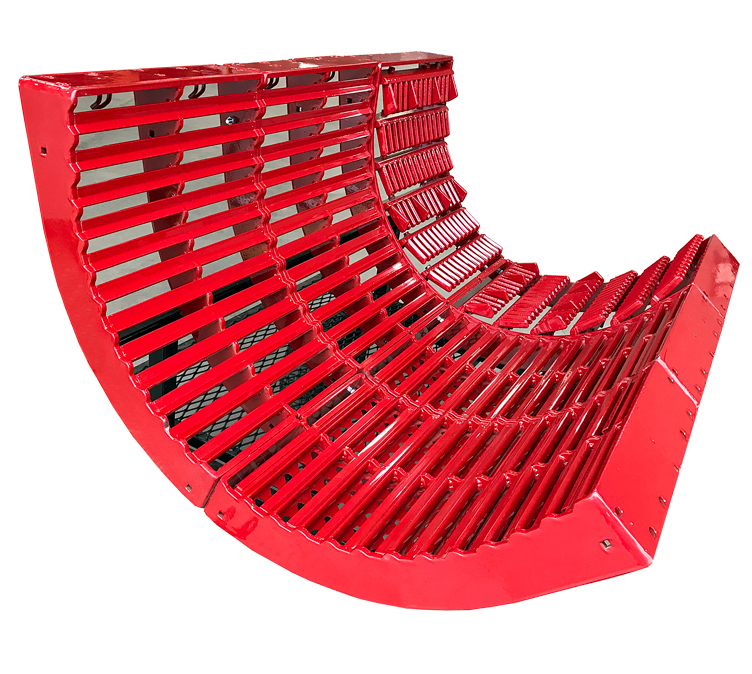

People are now getting in touch with the highly developed and engineered a concave system for threshing the crops using Aftermarket Combine Parts that prevents the loss of rotor and improves the quality of grain. The capacity of threshing all the crops is more with less damage to the grains. The concaves made of small-wire are more capable than the round-bar concaves.

The wheat which is hard to thresh, are kept on the plates for a longer period of time which ensures the complete threshing. Using the Aftermarket Combine Parts, the grains coming out are getting better as they prevent the contamination and conserves the seed. The small batches of grain threshing reduce the waste. The size and complexity of the grains don’t require the rotor to run tight.

The grinding of the wheat amazes the farmers and gives them the opportunity to enjoy the harvesting. A lot of farmers simply believes that using Aftermarket Combine Parts is simply the best way to get the maximum grain threshing.

Improved Provision for Greater Efficiency

The improved operation of Aftermarket Combine Parts has adopted the advanced mechanism for aggressively threshing the crop without any loss. The objective is sufficient to thresh without cracking the grain and damaging the wheat-cap. The art of the invention is an embodiment of the principle of threshing with greater efficiency which is the reason that how threshing the crop has become easier.

The appreciable convention of threshing the entire crop is propelled and pulled together by the Aftermarket Combine Parts model. The high-speed curved parts allow the grains to sieve and shake mechanically. The large pieces of the incomplete threshed grains returned to the cylinder where the process is repeated again.

Farmers can find the machine as a better investment as it provides the maximum grain threshing and tosses the remaining the loose grains. The characteristic of the yielded grain prevents the broken and is one of the resilient descriptions. The modern grain crop adjustment requires a good deal of effort in operating the machine.

Resilient Features of Threshing Machine

Quality

The highlighted part of the thresher functional part is its reliability and the structural design is superior. The compact assignment and specification is proof for the anti-rust and anti-moisture.

Efficiency

The combine parts of thresher produce highly efficient crops that separate husk and dust. The winnowing of the grain produces the production that gets separated and cleared.

Usage Application

The combined parts are used for wide application of threshing various crops like barley, rice, millet, wheat etc.

Cost-Savvy

The low breakage and the rate of removal have a greater advantage which saves the cost of labor and the time of harvesting. It is easily maintained and operated. The compact structure is highly equipped that runs smoothly in the field and the working is safe and durable.

The machine offers a rigid structure that has a greater drive and highly efficient rollers and powerful device that offers the better job of threshing. The grains get separated, flow down the screen, centrifugal rollers throw the culm and the threshing is done.