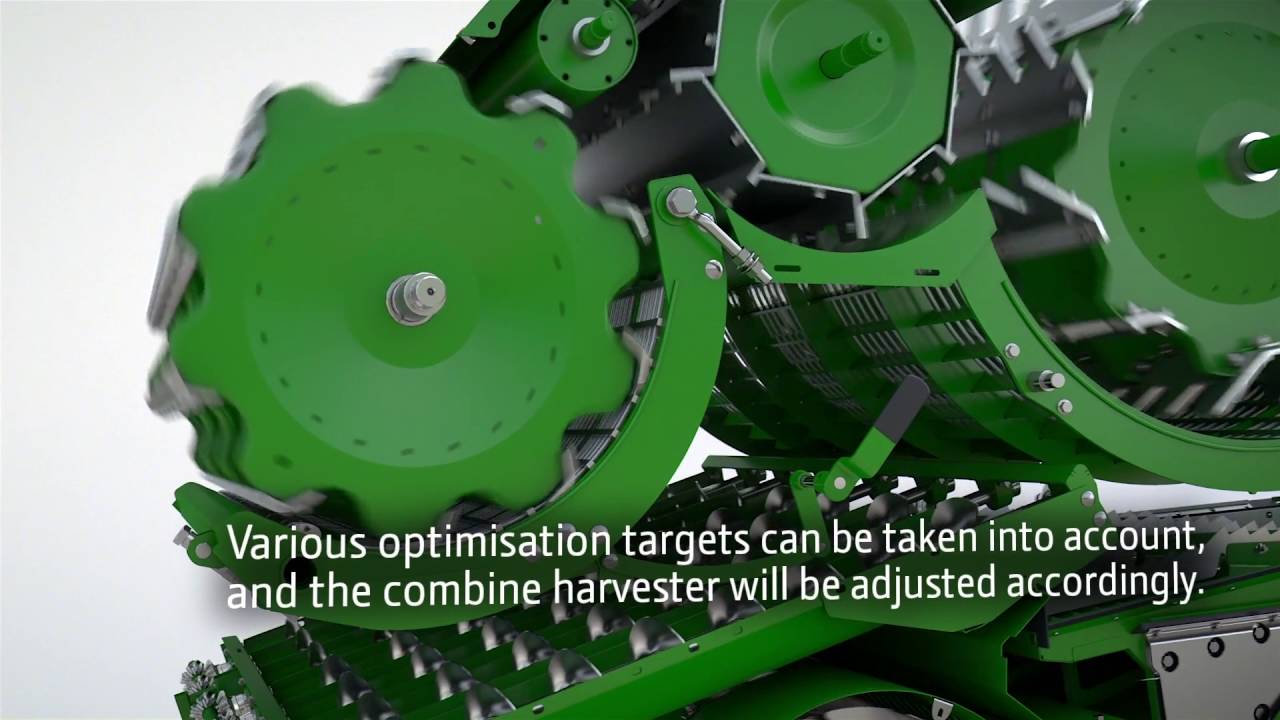

It’s essential that John Deere combine settings are set consolidated and accurately before heading onto the field the coming reap season. Sifting is a central zone. It is cultivated by scouring unthreshed material between the two harsh surfaces: the inward and the rub bars on the turning barrel.

With the John Deere combine settings, the material enters the front of the sunken from the feeder chain and goes over the inward, pushed along by the turn of the chamber. In a perfect world, just the grain ought to experience the sunken, and all the straw and debris should return out the between the inward and barrel onto the walkers or whatever is left of the pen.

Be that as it may, the John Deere combine settings are not constantly conceivable to accomplish. All the refusal will experience the inward with the grain, making the requirement for the strainers. Also, a portion of the grain may be done with the straw. Your activity on the ground is to get as near the perfect as could be expected under the circumstances.

There are two things to check while deciding consolidated effectiveness: What sort of misfortunes are on the ground behind the machine? What type of example is in the grain tank?

It is savvy with the John Deere combine settings to keep the strainers wide open so that everything sifted goes into the grain tank without experiencing the sifting barrel a second time. Individuals will, in general, close the base sifter when they find unthreshed material in the tank. However, that remarkably cuts limit.

Once in a while, you will have the Whitecaps in the grain tank. The allurement is to close that base sifter only a bit. That will tidy up your example. Additionally, lessen limit and include a couple of progressively split pieces.

When setting the shifting territory, place the chamber speed first. A general principle is that you set it as quick as you can without splitting grain.

The active braking is the understanding of speed, while pounding happens when grain is gotten among chain and sprocket or inward and rub bar. You will have harmed parts regardless of how cautious you are. You ought to get short of what one percent.

Speed gives limit just as energy to help the machine through the predicament and keeps the barrel from slugging. Speed may be constrained in dry conditions since breaking straw will over-burden the machine and cause problems.

In rotating of the John Deere combine settings, changing the sifting barrel speed, additionally, implies changing the division chamber speed. Since detachment is cultivated by outward power, the quicker it turns, the more it can deal with. Once more, this decides limit.

Concluding that it is, additionally, critical to set the leeway between the inward and the chamber. When you push the sunken up more tightly against the chamber, it powers more grain through the inward.