Harvesting Success: A Guide to Choosing the Best Concaves for Your Combine Harvester

A combine harvester is an important piece of Agriculture equipment for any farmer, as it helps them to harvest crops quickly and efficiently. The concaves in the harvester are one of the critical components responsible for separating the grain from the crop. However, with so many different concave options available on the market, choosing the best one for your needs can be challenging. Today, we will guide you through the process of choosing the best concaves for your combine harvester.

What are Concaves?

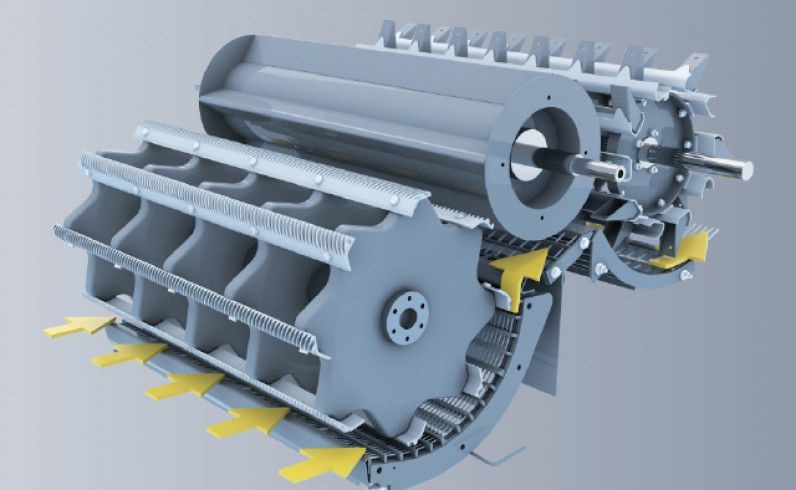

Concaves are the metal plates located in the threshing area of a combine harvester. They are responsible for separating the grain from the crop by forcing it through a narrow gap between the concaves and the rotor. The concaves come in different shapes, sizes, and configurations, depending on the type of crop being harvested and the conditions in which the crop is growing.

What do Concaves do?

The concaves play a vital role in the harvesting process, as they are responsible for separating the grain from the crop. The concaves work by applying pressure to the crop as it passes through the threshing area, which causes the grain to separate from the rest of the plant material. The separated grain then falls through the concave grates and into the grain tank, while the remaining material is ejected from the back of the combine.

Qualities of Good Concaves

Good concaves should be made from high-quality materials that can withstand the rigours of the harvesting process. They should also be designed to provide maximum separation efficiency, while minimizing grain damage and losses. Additionally, good concaves should be easy to install and maintain and compatible with a wide range of combine harvester models.

Tips to Choose the Best Concaves for Your Harvester

When choosing the best concaves for your harvester, there are lots of factors that you should consider. Firstly, you should think about the type of crop you will be harvesting, as different crops require different concave configurations. For example, crops such as wheat and barley require a narrow concave gap, while crops such as corn and soybeans require a wider gap.

You should also consider the conditions in which the crop is growing, as this can affect the hardness and moisture content of the crop. In dry conditions, for example, the crop may be harder and more brittle, which requires a more aggressive concave configuration to ensure maximum separation efficiency.

Another factor to consider when choosing concaves is the harvesting capacity of your combine harvester. If you have a high-capacity harvester, you may need to choose concaves that are designed to handle higher volumes of crop without sacrificing separation efficiency.

How Estes Concaves Win Over its Competitors

Estes Concaves is a leading manufacturer of high-quality concaves for combine harvesters. Their concaves are designed to provide maximum separation efficiency while minimizing grain damage and losses. Estes concaves are made from high-quality materials that can withstand the rigors of the harvesting process, and they are compatible with a wide range of combine harvester models.

Estes concaves offer several advantages over their competitors. Firstly, they are designed to be more durable, which means that they can withstand the rigors of the harvesting process for longer without needing to be replaced. Estes concaves are also designed to provide better separation efficiency, which means they can separate the grain from the crop more effectively than other concave brands.

Another advantage of Estes concaves is that they are designed to be installed and maintained easily. This means that you can quickly and easily replace your existing concaves with Estes concaves, without needing to hire a professional or spend a lot of time and money on maintenance.

What to Look for When Buying Concaves?

When buying concaves, there are several things that you should look for to ensure that you get the best quality product for your needs. Firstly, you should look for concaves that are made from high-quality materials, such as heat-treated steel, as these materials can withstand the stresses of the harvesting process for longer.

You should also consider the design of the concaves, as different designs are better suited to different types of crops and harvesting conditions. Look for concaves that have a design that is specifically tailored to the type of crop you will be harvesting and the conditions in which it is growing.

Another important factor to consider when buying concaves is compatibility. Make sure that the concaves you choose are compatible with your combine harvester model, as using incompatible concaves can lead to reduced separation efficiency and increased grain damage.

Finally, you should consider the reputation of the manufacturer when buying concaves. Look for manufacturers with a track record of producing high-quality products that are designed to provide maximum separation efficiency and minimum grain damage and losses.

In conclusion, choosing the best concaves for your combine harvester is an important decision that can have a significant impact on the efficiency and profitability of your farming operations. By considering the type of crop you will be harvesting, the conditions in which it is growing, and the compatibility of the concaves with your combine harvester, you can make an informed decision that will help you to maximize your yield and minimize grain damage and losses. Estes Concaves is a leading manufacturer of high-quality concaves that are designed to provide maximum separation efficiency and durability, and they are a great option for farmers looking to optimize their harvesting operations.