Combine Concaves Purpose

Whether your harvest is a John Deere or a Case IH combine, your concave plays a vital role in the quality of your harvested crop. The combine concave performs two important functions- threshing and separating. The threshing process frees the seeds from the plants. Then the separation process moves the seeds away from the chaff.

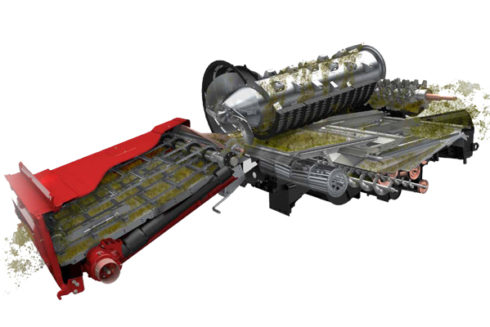

How Combine Concaves Work

In concaves for combines, friction among the rotating cylinder, the incoming crop, and the concave results in the threshing process. The clearance between the cylinder and the concave is adjustable. Once the crop enters the clearance, it gets squashed by the cylinder against the concave and smaller parts start to sift through the openings. As a result, the grain is separated from the plants.

The clearance distance, the bar and wire patterns of the concave, the speed of the rotor, and the crop types determine how clean the samples turn out in the grain tank. It takes a bit of experience to understand how all these factors influence the process.