A combine harvester is a kind of agricultural machinery designed to harvest various grain crops efficiently and effectively. This harvester’s name is derived from the fact that it can combine three unique harvesting processes, as follows:

Reaping

When crops are harvested after they have achieved their peak maturity, they are “cut” (or “hacked”).

Threshing

It sifts through the plant material to get at the edible grain while leaving behind the inedible chaff.

Winnowing

Finally, the grain was freed from the straw after a lengthy wait.

All of the preceding processes are combined into a single operation.

If a combined harvester can harvest many crops simultaneously, it is known as a multi-crop combine.

• Barley

• Wheat

• Maize

• Oats

• Sorghum

• Soybeans

• Rice

• Sunflowers

Following harvest, the straw removed from the crops is left on the field. There are still some leaves and stems in this straw that hasn’t been picked. It is chopped and spread out throughout the area, baled for feeding cattle, or used as bedding before being tilled back into the soil. The rotary combines work perfectly there.

Some of the advantages of using a combined harvester include the following.

Rotary combines have a substantial benefit in terms of simplicity of use. More moving parts mean more things might go wrong or need to be serviced, which means more downtime. As a result, rotary combines can process more grain while taking up less area. An average-sized conventional combine would be more significant than many houses compared to an equivalent-sized rotating combine. Rotary combines are smaller and easier to transport. Rotating combines are also much gentler on crops like malt barley, peas, and lentils, which are particularly delicate. Finally, since the rotary combine harvester has a smaller number of parts, it is easier to clean than other harvesters.

Using a combined harvester instead of harvesting by hand reduces the amount of waste grain. Because of the time and effort required to cut, tie, haul, and transport the crop while harvesting manually, a combined harvester ensures that no grain is lost.

It takes about one hour to combine harvester equipment to harvest and process an acre of land. At least 12 workers a day are needed to perform the same job manually, which doesn’t include the threshing step.

Each step of the threshing process must be completed manually, which adds several days to the entire processing time and many more days to the cleaning process when utilizing the manual method. As a result, it takes at least a week from the time of harvest until the crop is ready for sale when harvested manually. However, harvesting using a combined harvester may provide a ready-to-sell crop in less than an hour.

• The market is willing to pay more for grain harvested using a combine because it is cleaner than grain harvested by hand.

• If the labor costs associated with manual harvesting are considered, mechanized harvesting is much less expensive.

Last Words

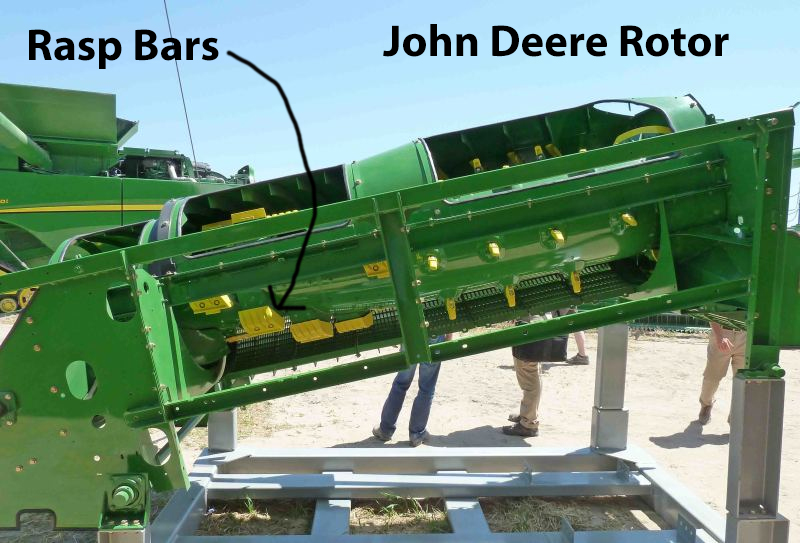

Using a chain and a flight elevator, the crops are carried into the feeder throat, also known as the feeder house. This is followed by a process known as the “thresher,” a rotating drum with rasp bars attached to it. There are two concaves under the combine drum, which hold the rasp bars that may be discovered.