Do you have a farm to harvest? Then you must be using combine concaves. You should select the best IH combine so your harvested crop does not get damaged. Combine concaves play an important role in crop harvesting. A good combine concave will help protect the crop quality as well. You can collect more information related to aftermarket combine parts online.

Important functions of aftermarket combine parts :

In general, two of the most important functions are only performed by the combined concaves

a) Any combine concave has been designed to carry out the threshing task during the harvest season.

b) The combined concaving machine will also perform the task of separating the crop harvest from its chaff and seeds.

c) there must be good ground clearance.

The mode of action

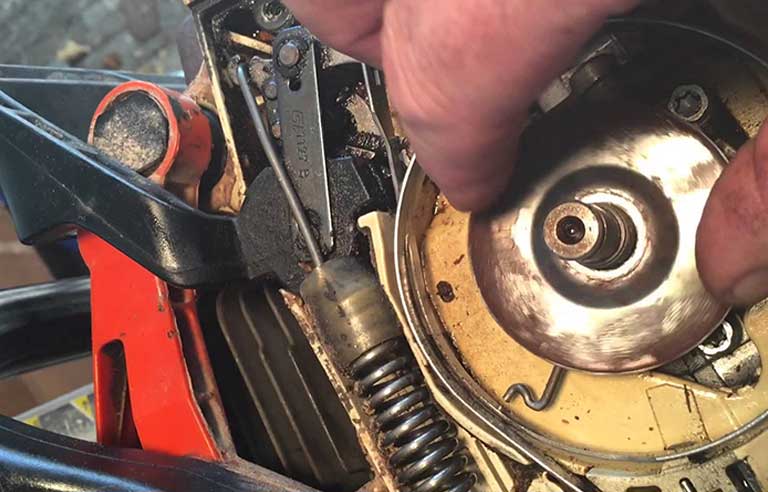

The MOD part refers to the working process. A concave combine is designed to work on a simple principle. The main machine is installed with a specific type of rotor cylinder. This is a part of the machine that rotates at a very high speed. This high-speed rotation is important during the threshing process. The cylinder and the concave will have a clearance in between. The clearance in the machine area is adjustable type. A crop that is harvested by the farmer will be allowed to enter into the clearance area. Adjustment is made such that only small-sized parts will be allowed to pass through the clearance. As a result of this action, the grain part of the harvest is easily separated from the plant.

What helps in the separation process?

The high speed of the rotor is what will separate the crop and the chaff or even the crop from the seeds. A high spinning rotor is made up of a lot of meshed parts. These are the adjustable parts that will allow small size grains and chaffs to pass through. You can also collect all details of the aftermarket combine parts. The grain and seeds that are separated during the process, will get collected in the grain bag. This prevents the grain and chaff from getting scattered.

How to prevent grain damage?

It is obvious that if clearance is not well maintained then grain particles can get damaged. The clearance must be well maintained in between the cylinder and concave. If the right size is not selected then grain particles will get damaged. It will also result in uneven material flow during the harvest. If the space in between is too wide then the plant parts and unwanted chaff will also be allowed to pass through the mesh. If this happens then the grain will remain mixed with the chaff of the plant parts. It may not be possible to separate the grains manually. Thus, you need to use a quality combine concave machine.

Summary:

You can collect more information related to aftermarket combine parts from an expert dealer. Many experts are willing to provide with right set of information related to the clearance settings. You can also look for best-recommended settings online.