When the harvest season starts, one needs to have the machine in perfect condition. To improve the quality of the harvest and prevent losses, we have to adjust the combine concave setting. Here are the important things you have to look at before you begin the harvest.

The Appearance of Damaged Grain

One reason you see cracked grains is when you set the drum too close to the concave. Increase the combine concave setting distance 10 mm at a time. If the problem persists, adjust the drum speed. High drum speed can separate the grain because of the increased centrifugal force. Damaged grains can also appear because of the slowing of the speed of the intake grain, or there is a slowing of the return elevator chains.

Using the Proper Setting for the Harvester

On average, for the normal combine concave setting, you can harvest up to 200 acres on a hot dry day. There are three operations combined – winnowing, reaping, and threshing. One has to use a high-quality top chafer to get the best results. One has to exercise more caution when there is high moisture in the crops. This year the agronomists expect more moisture, which is why you have to open the bottom sieve as much as you can. If necessary, take it out altogether. This will allow the grain to flow well. If you have a small-sized grain like barley and wheat, you can use a narrow wired concave. By setting the clearance too tight, you cause damage to the grain.

Setting for the Upper Sieve

The front third of the upper sieve must be clean. You will only see the mixture of the grain and the crop residue in the middle section. If there is grain in the front third, adjust the combine concave setting to open the sieve a little to allow the grain to flow more freely.

The Appearance of Trash in the Tank

Trash appears when the fan speed is too slow. There is over threshing in the tank that you can rectify by decreasing the drum speed. The trash should only appear in the rear third of the upper sieve. But if you see grain here, open the sieve to let the grain flow out. Also, if the combine concave setting for the threshing is very aggressive, the loading in the top sieve will be heavy. This often happens in dry brittle crops, and so you have to reduce the speed of the threshing operation. Try not to have the top sieve as wide as possible because it will give you a dirty sample.

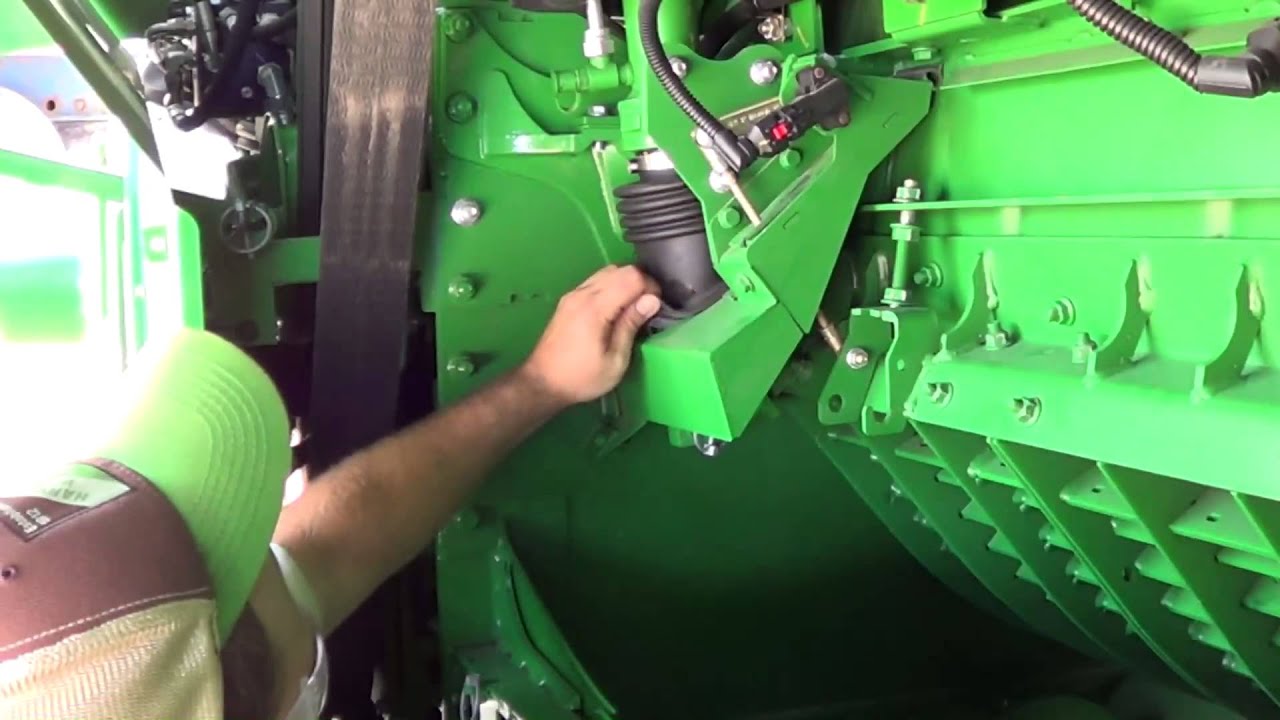

The Setting for the Snapping Roll

Keep the combine nearly full at all times to reduce the impact on the grain. Get a smooth, even flow of crop material by adjusting the settings. Set the combine concave setting for the striper plate and snapping roll as per the thickness of the stalk. Always operate at full throttle. Adjust snouts to touch the ground. If you have plants lodged into the ground, float the snouts a little and reduce the speed as needed. According to the condition of the crop, you can adjust the snapping roll and ground speed. Go fast as long as you don’t plug the head of the threshing mechanism.